IMM ranges from 50-3000 tons, prototype, production, supporting equipment and fixtures.

Decades of experience within multiple sectors including consumer, industrial and automotive.

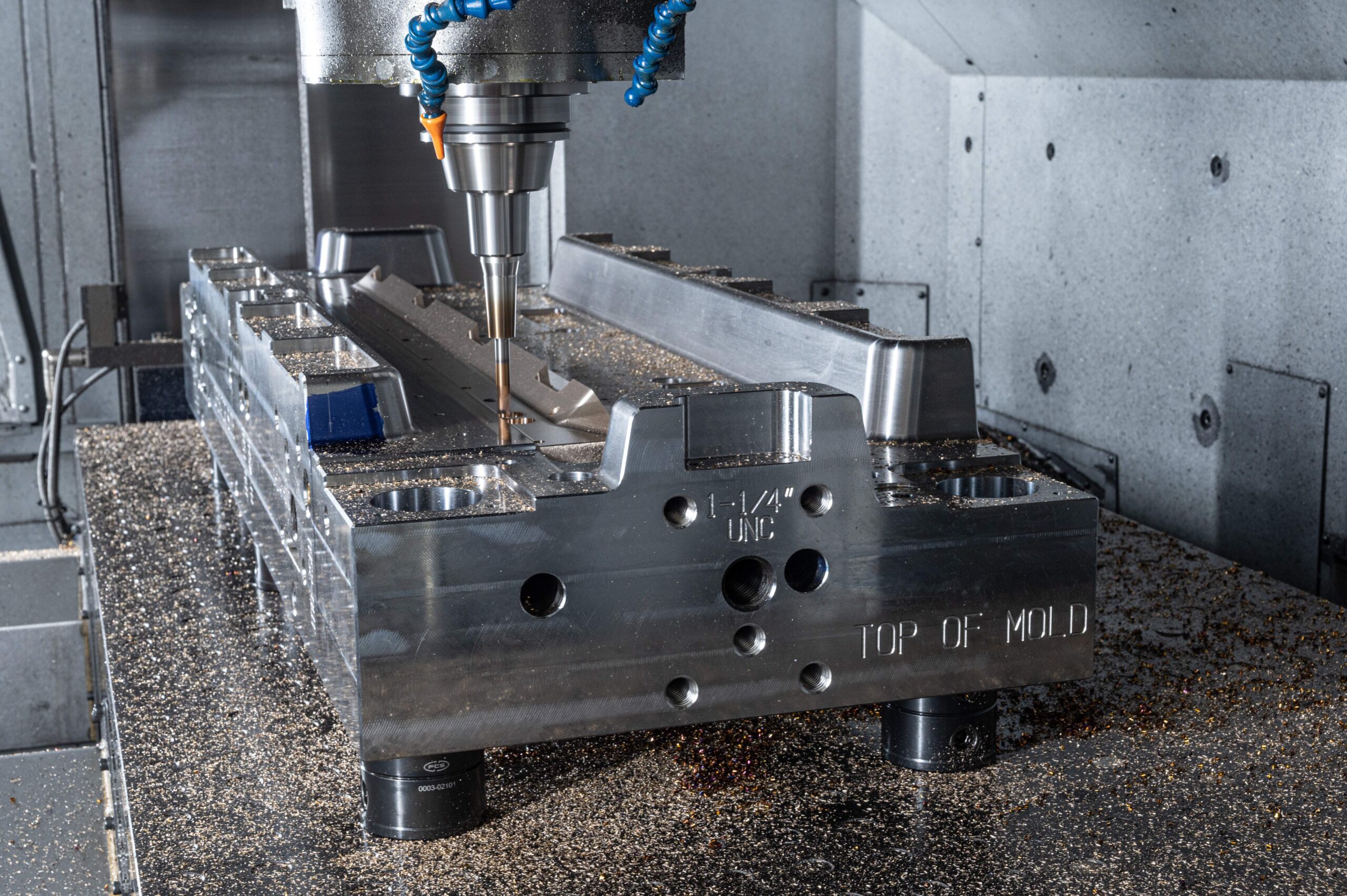

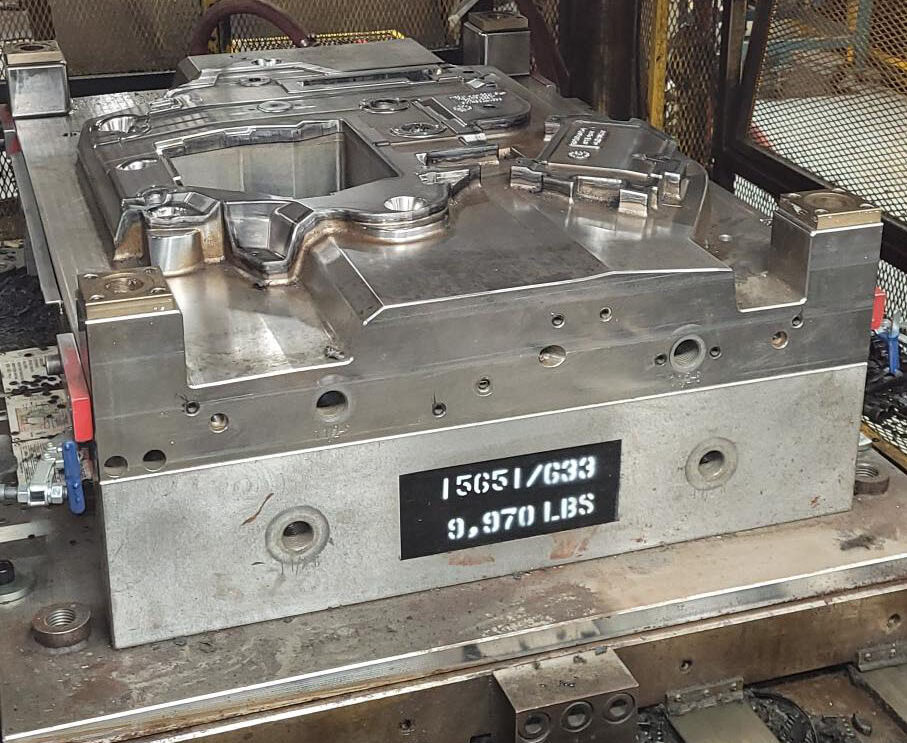

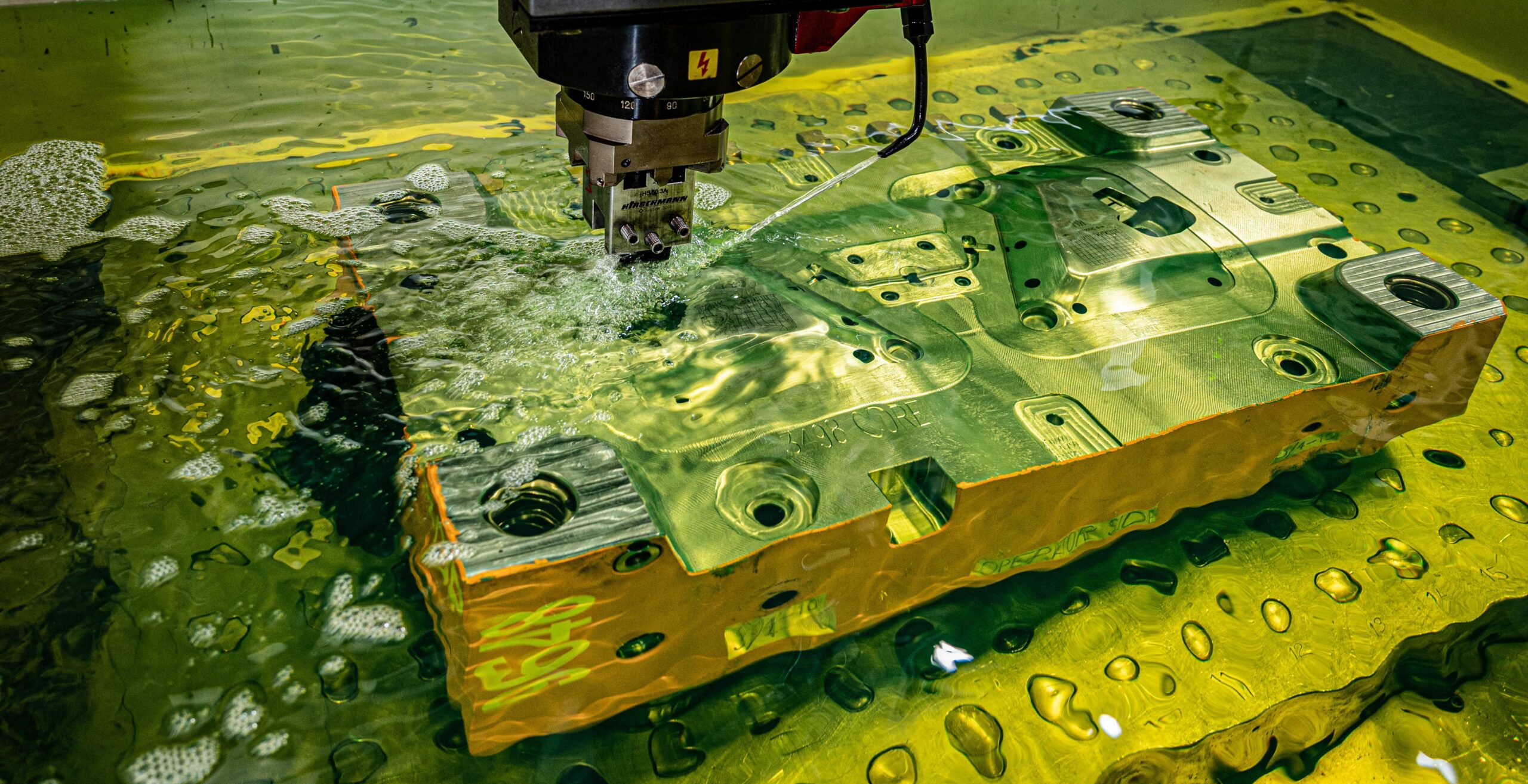

Arlen Tool + Machining Division offers a variety of high-precision machined components to the automotive, aerospace, military, oil, and gas sectors. Services offered include high precision 3 and 5-axis machining of highly complex large and small components. Arlen Tool + Machining also offers full machine shop services for all of your small component manufacturing needs.

Single and multiple cavities, prototype or production, multilayer fuel systems to monolayer washer bottles and SCR tanks. The following OEM customers through our Tier 1 partners: GM, Ford, Chrysler, Honda, Toyota, Fiat and Polaris.

Mechanisms, Features, Materials

Specializing in tooling to produce chrome plated plastic injection parts.

Arlen Tool + Machining specializes in:

Arlen Tool Group, your partner in Tooling for all your Compression Molding needs.

We can offer tooling supplied domestically within China and/or exported to N.A.